SERVICES

Virtual Design and Construction

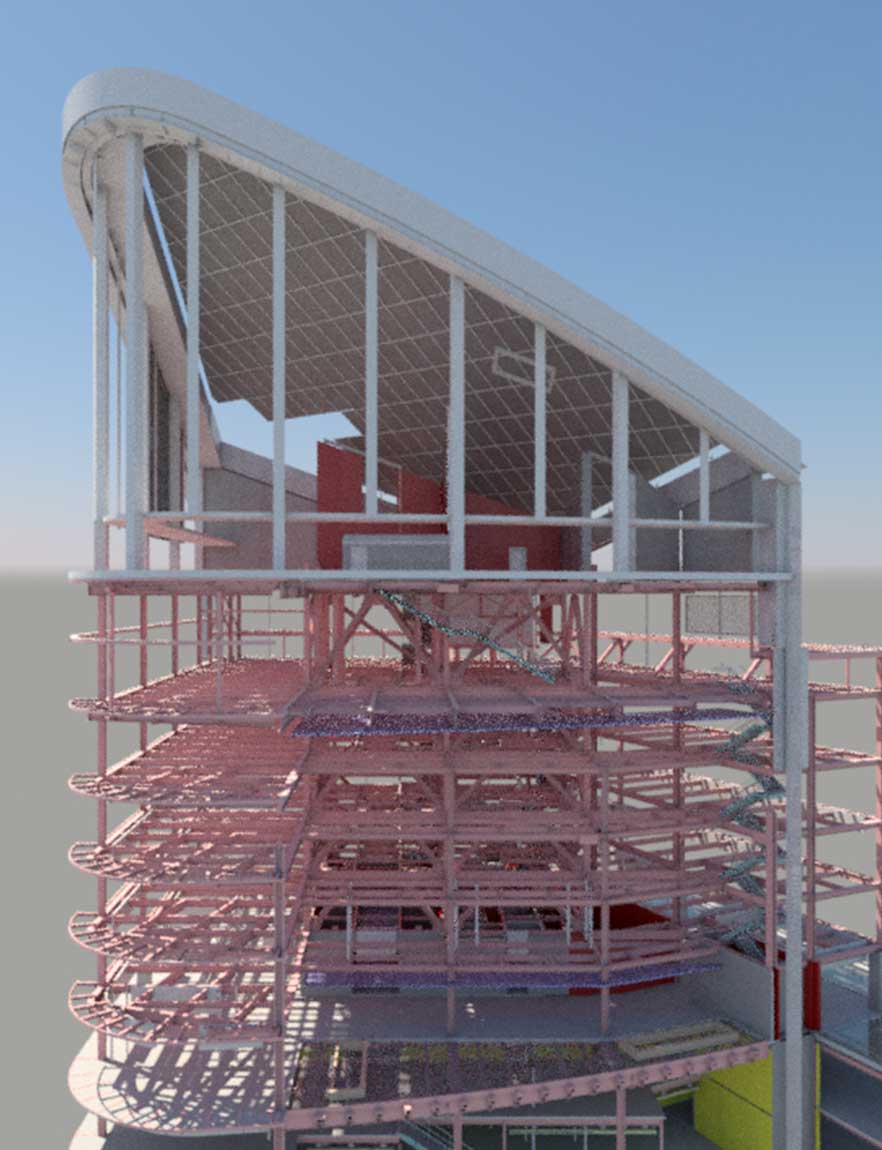

PJ Dick’s virtual construction coordinators use the latest construction technology to help maximize construction efficiency. Using tools such as laser scanning, building information modeling (BIM), and virtual reality, our virtual design and construction experts (VDC) help the team enhance collaboration which can improve scheduling and reduce risk.

Building Information Modeling (BIM)

Quantity takeoff

MEP coordination

Constructability analyses

Clash detection analyses

Construction methodology

Virtual mockups

Shop Drawing Coordination (MEP)

Subcontractor off-site prefabrication

VDC Reduces Risk and Promotes Efficiency

Virtual design and construction technology helps create the most accurate possible overview of a construction project. PJ Dick uses building information models (BIM) to provide the team with precise measurements and clear predictability for the project’s result.

Virtual design and construction provides highly effective preconstruction tools for building more efficiently, such as:

Clash detection

Building a multi-disciplined model

Creating virtual mockups

Increasing predictability, reducing risk, and reducing cost

Full understanding

Enhanced constructability

Laser Scanning Informs Virtual Design and Construction

The term “as built” does not always mean “as is.” Whether the challenge of the day relates to knowing the square footage of a building’s roof, or requires the exact clearance heights in a mechanical room, having a true understanding of the existing conditions can have a significant impact on any decision, and save thousands of dollars. PJ Dick uses high-definition laser scanning to measure and document every part of a job site. With precise data on hand, we’re able to make informed decisions that help keep the project on track, ensure accurate construction, and save money. Our in-house laser scanning and building information modeling technology enables us to:

Quickly scan existing conditions

Convert data to a 3D model to expedite mechanical/electrical coordination

Create fabrication to meet your schedule requirements

Virtual Design and Construction Maximizes Collaboration

Hundreds of people are involved in any given construction project, including dozens of professionals engaged in the preconstruction and planning phases. Virtual design and construction makes it easier and more effective to keep everyone on the same page throughout the entire process.

With engineers, architects, planners, supervisors, and other key personnel all connected to the same accurate information, our team can build with confidence. It’s one more way PJ Dick takes advantage of every possible tool to help our customers achieve their visions.