With decades of construction expertise to bring to the table, PJ Dick has earned its place as an industry leader. Through years of hands-on experience, we have honed our approach to deliver the greatest possible value to the clients and communities we serve. What the industry calls “lean construction” has become a hallmark of the work we’re known for, and it can serve as a blueprint for the success of your next project.

Five Effective Lean Construction Techniques

Efficiency is the foundation of successful construction practice. Over the years, our dedication to this simple principle has proven its worth tenfold, culminating in the tailored practices we’ve adopted to streamline our process. To achieve our objectives of completing projects on time, within budget, and maintaining the highest standards of quality, we’ve honed a set of essential lean construction techniques to deliver reliable results.

1. The Last Planner System (LPS): Our team has embraced the Last Planner System, or LPS, as a means to harmonize the efforts of multiple parties. This helps us to ensure predictable and streamlined project workflows, fostering clear-cut communication between project participants for improved collaboration. The result is a process that eliminates bottlenecks, reduces disruptions, and minimizes delays.

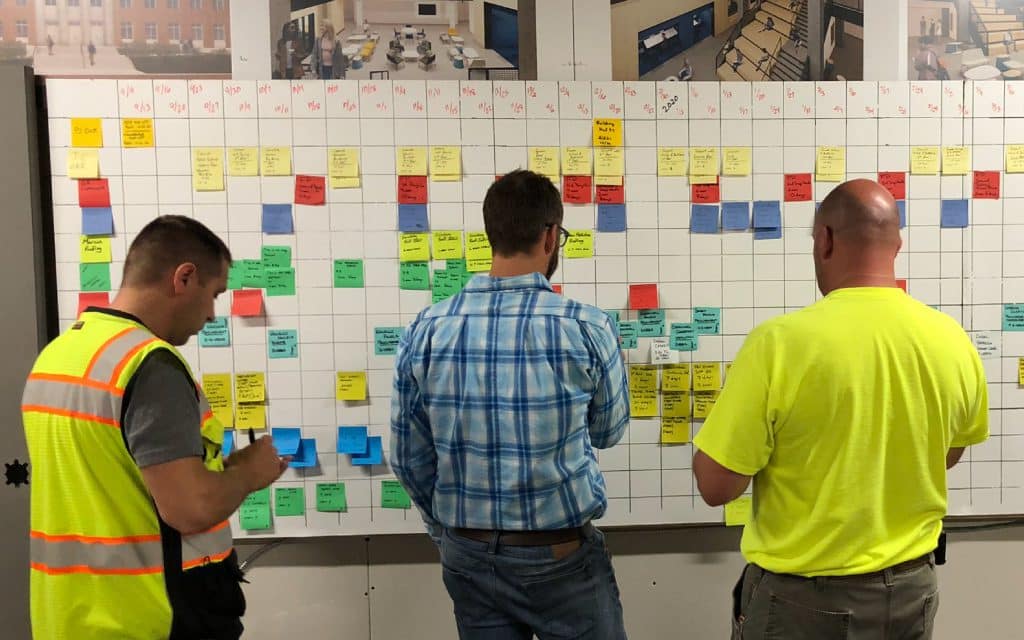

2. Pull Planning Meetings: Before the first brick is laid, our team makes a priority of organizing pull planning meetings, which help to facilitate a holistic view of the project between stakeholders. These meetings create an open dialogue where all parties can discuss their unique roles in conjunction with one another, allowing for more effective planning, cooperation, and a collective understanding of the product’s objectives.

3. Conditions of Satisfaction: A central goal of our early meetings is to ensure all stakeholders come to a mutual understanding of the project’s conditions of satisfaction. Once agreed upon, these criteria become the parameters that will guide every decision throughout the project, aligning all efforts toward a carefully defined common goal.

4. Target Value Delivery: In order to best meet the operational needs of our project owners, PJ Dick has made collaboration with architects a central component of our approach. With the objective of maintaining the integrity of the defined budget, we work with our architects to reach an optimal design that maximizes the value of an owner’s investment..

5. Supply Chain Communication: Efficiency is a principle which extends just as much to materials as it does to time. We’ve found this is best achieved through comprehensive supply chain communication. By coordinating the delivery of essential materials at key points on the timeline, we can both reduce unnecessary wait times and mitigate the risks of excess inventory, which might otherwise be subject to potential damage or theft.

Practical Application: Erie Hall at Penn State Behrend

PJ Dick’s approach to lean construction is best demonstrated in action. The results of our commitment are exemplified in the success of Erie Hall, a project recently completed at Penn State Behrend. Today, the hall stands as a proud testament to the effectiveness of our lean construction strategies.

In collaboration with both Penn State and our design team, we first established our conditions of satisfaction to ensure a mutual alignment on the project goals. This, in turn, helped us to foster a common language of collaboration and define our expectations for team behavior and culture.

Through the attentive use of a project dashboard conveyed in A3 Report formatting, PJ Dick was able to provide Penn State with a comprehensive and straightforward monthly update on the project’s progress and associated budget. This transparent system of reporting helped us to facilitate the project’s smooth progression, promptly identifying and addressing any deviations from the established plan and timeline.

Throughout the project, PJ Dick also made use of Team Health Syncs to perform monthly “temperature checks” for the entire project team. These evaluations served to confirm the team’s continued functionality, ultimately resulting in sustained morale and healthy collaboration.

Over the course of Erie Hall’s construction, PJ Dick conducted three collaborative Pull Planning sessions. These meetings allowed the team to properly coordinate and schedule remaining work with the input of all parties. Through team-centric planning and streamlined workflows, Penn State Behrend’s Erie Hall project saw exceptional results achieved with minimal waste in a distinct and predictable timeframe.

Advantages for Project Owners

When executed properly, lean construction practices stand to benefit project owners as well as the contractors, subcontractors, and trade partners involved. Owners who invest in lean construction projects can expect to see tangible improvements over traditional methods, including:

1. Reduced Costs: By eliminating waste from both the design and construction processes, lean construction reduces costs across multiple dimensions, from transportation and inventory expenses to billable work hours. The result is a lower total investment for project owners.

2. Shortened Timelines: When implemented successfully, lean construction practices will coordinate various workflows to minimize wait times, rework, and other instances which may cause delays to the projected schedule. This is particularly appealing for businesses where time-to-market is a top priority.

3. Improved Quality: By eliminating unnecessary expenditures in time, effort, and resources, lean construction narrows a project’s focus to the essentials, as defined by the conditions of satisfaction. This streamlining allows teams to allocate more time and attention to the important elements, resulting in superior quality across the board.

Explore Lean Construction with PJ Dick

As experienced pioneers in lean construction, the team at PJ Dick is proud of the part we’ve played in reshaping the landscape of project management in our industry. Driven by our values of safety, quality, integrity, family, and community, our commitment to lean construction philosophies has ushered us into a new era of efficiency and effectiveness. To learn more about our lean construction methodologies, or to discover how these practices can help to shape the success of your next project, contact the award-winning PJ Dick team today.